- #ASME Y14.5 2009 BASIC DIMENSION INSPECTION HOW TO#

- #ASME Y14.5 2009 BASIC DIMENSION INSPECTION PROFESSIONAL#

Product engineers, manufacturing engineers, CAD designers, quality inspectors, and other engineering and manufacturing personnel will all benefit from becoming fluent in GD&T. This course is ideal for anyone who has a need to apply or interpret geometric tolerances on a product print.

#ASME Y14.5 2009 BASIC DIMENSION INSPECTION PROFESSIONAL#

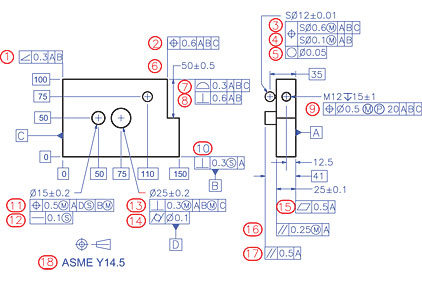

He is certified as a Senior-Level GD&T Professional by the American Society of Mechanical Engineers. John-Paul Belanger is president of Geometric Learning Systems, based in Rochester Hills, Michigan. Marburger Science and Engineering Auditorium (Room S100)Ģ1000 West Ten Mile Road, Southfield, MI 48075 The class is a lecture format, with ample opportunity for questions, and participants are welcome to bring sample prints (with or without GD&T already applied) to discuss with the instructor during breaks or after the class.Ī spiral binding book for GD&T will be provided. Participants will learn the basic definitions and rules, the importance of datums, the meaning of each tolerance, and the impact on manufacturing and gaging.

#ASME Y14.5 2009 BASIC DIMENSION INSPECTION HOW TO#

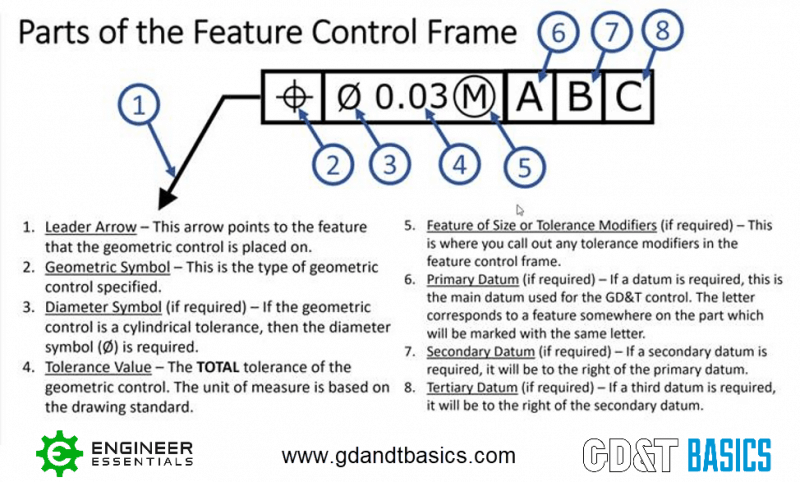

This one-day course covers the GD&T system per ASME Y14.5-2009, including why it reduces costs, how to interpret the symbols, and how to apply these tolerances correctly. To better define a product, geometric dimensioning and tolerancing (GD&T) is often used as a symbolic way to show tolerances on mechanical drawings.

S100 (Marburger Science and Engineering Auditorium)Ĭomplimentary breakfast and lunch providedĬontinue Education Unit (CEU) / Professional Development Unit (PDU) Credits will be available and a Certificate of Accomplishment will be provided. Smart Manufacturing and Lean Systems Research Group

0 kommentar(er)

0 kommentar(er)